Higher and foundation tiers

A life cycle assessment (LCA) is a way to try and measure the total impact on the environment that a manufactured product has. A life cycle assessment for a particular product should look at every stage of its life from obtaining the raw materials needed to manufacture the product to the environmental impact of its manufacture and use and finally the impact on the environment when the product reaches the end of its useful life and is disposed of. A properly worked out LCA should enable you to decide for example whether it is worthwhile recycling a product or simply manufacturing a new replacement product if this has a smaller environmental impact.

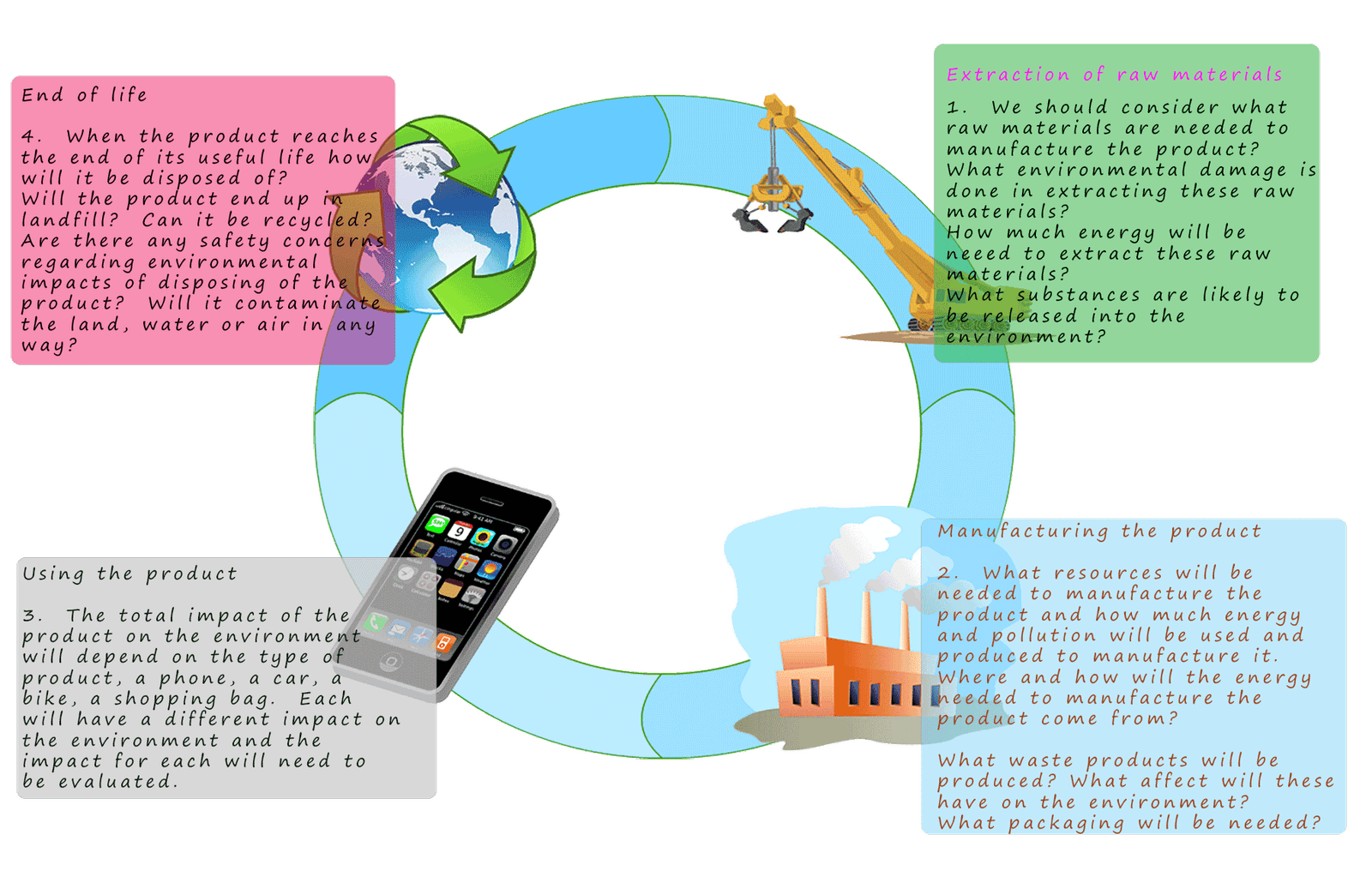

The life cycle assessment usually has 4 stages:

Below is a LCA comparing the use of plastic carrier bags against using paper bags. By comparing the LCAs for paper and plastic bags it should be possible in theory to make an informed decision as to which bag will cause less environmental damage throughout its life and whether it is better to recycle or make new replacement bags.

| life cycle assessment stage | plastic carrier bag | paper carrier bag |

|---|---|---|

| stage 1 - raw materials | Plastic bags are made from monomers obtained from crude oil. Crude oil is a limited finite resource which requires large amounts of energy to extract it from under the sea or from the land and to transport it to an oil refinery. |

Paper bags are made from wood pulp or from recycled paper products. Using recycled products will have less of an environmental impact than cutting down trees to make wood pulp. Also saves land if recycled paper products are used. Making paper bags is sustainable since more trees can always be planted, however trees take years to grow to a suitable size for felling and there will be large energy costs and pollution in felling, transporting and replanting tress. |

| stage 2- manufacturing the product | Plastic bags can be made very cheaply and in large quantities very quickly. The crude oil needed to make the plastic bags needs to be further refined at the oil refinery. Further chemical processes, namely cracking and polymerisation are then required to make the plastic bags. Each step uses large amounts of energy and will produce large amounts of carbon dioxide; a greenhouse gas. Ultimately this process is not sustainable since crude oil is a finite resource and will eventually be used up. |

Paper bags made from wood pulp will require large amounts of energy and water to process the pulp. Lots of waste material will be produced which may cause environmental damage especially to aquatic habitats. Manufacturing process will produce smaller quantities of bags than can be produced in any given time period compared to plastic bags. |

| stage 3 - use | Can be reusable and can last many months. |

Paper bags are not as strong as plastic bags, especially if they get wet. Can realistically only be used a few times. |

| stage 4- disposal | Unlikely to be recycled by the vast majority of people. Large amounts end up in landfill where they take decades or longer to decompose and rot down. |

Easy to recycle paper bags. Paper bags will decompose quickly in the environment. |

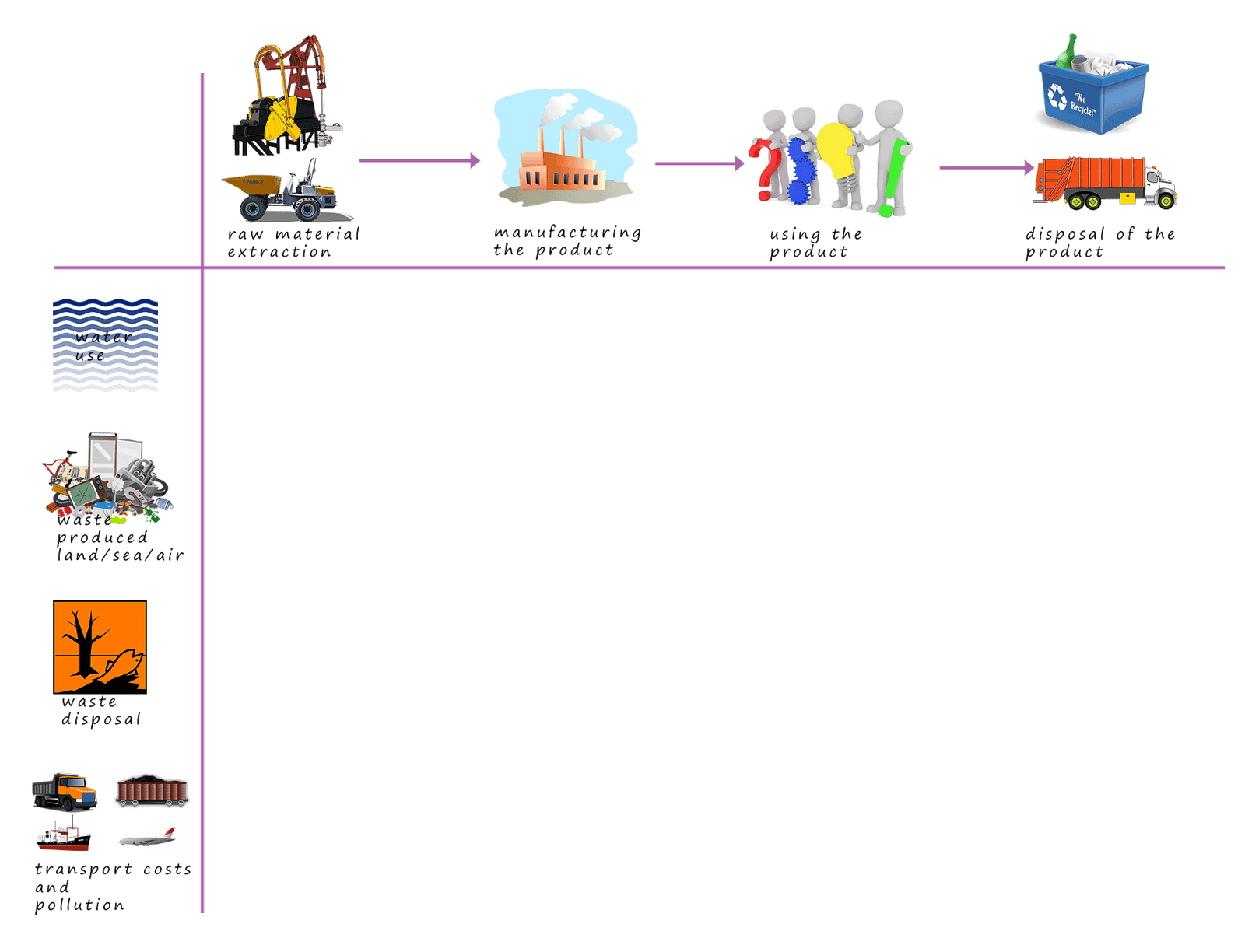

To help in getting started writing a LCA for a particular product the chart below may help. The top row of the chart covers the 4 key areas in the life cycle assessment:

The amount of energy and natural resources used over the lifetime of a product is usually relative easy to calculate. Scientists can calculate the amount of energy used in manufacturing, transporting and extracting a material. However it is not so easy to measure the environmental impacts of certain products or pollutants easily. Some of these measurements require judgements to be made by people and these judgements are not always reliable and are open to bias. It is possible that the people making these judgements may be trying to push their own ideas and agenda. Different people can make different judgements about the same thing simply because they have different agendas to pursue and their judgements make not be entirely accurate and made with all the relevant facts taken into account. This could result in the production of a LCA that does not show the true environmental impact of a product and this could quite easily be used by a manufacturer to mislead consumers about their product. Therefore it is important to know who has completed the LCA before you make any of your own decisions and judgements.